Latest News

We are becoming

SPIE

Learn more

SPIE

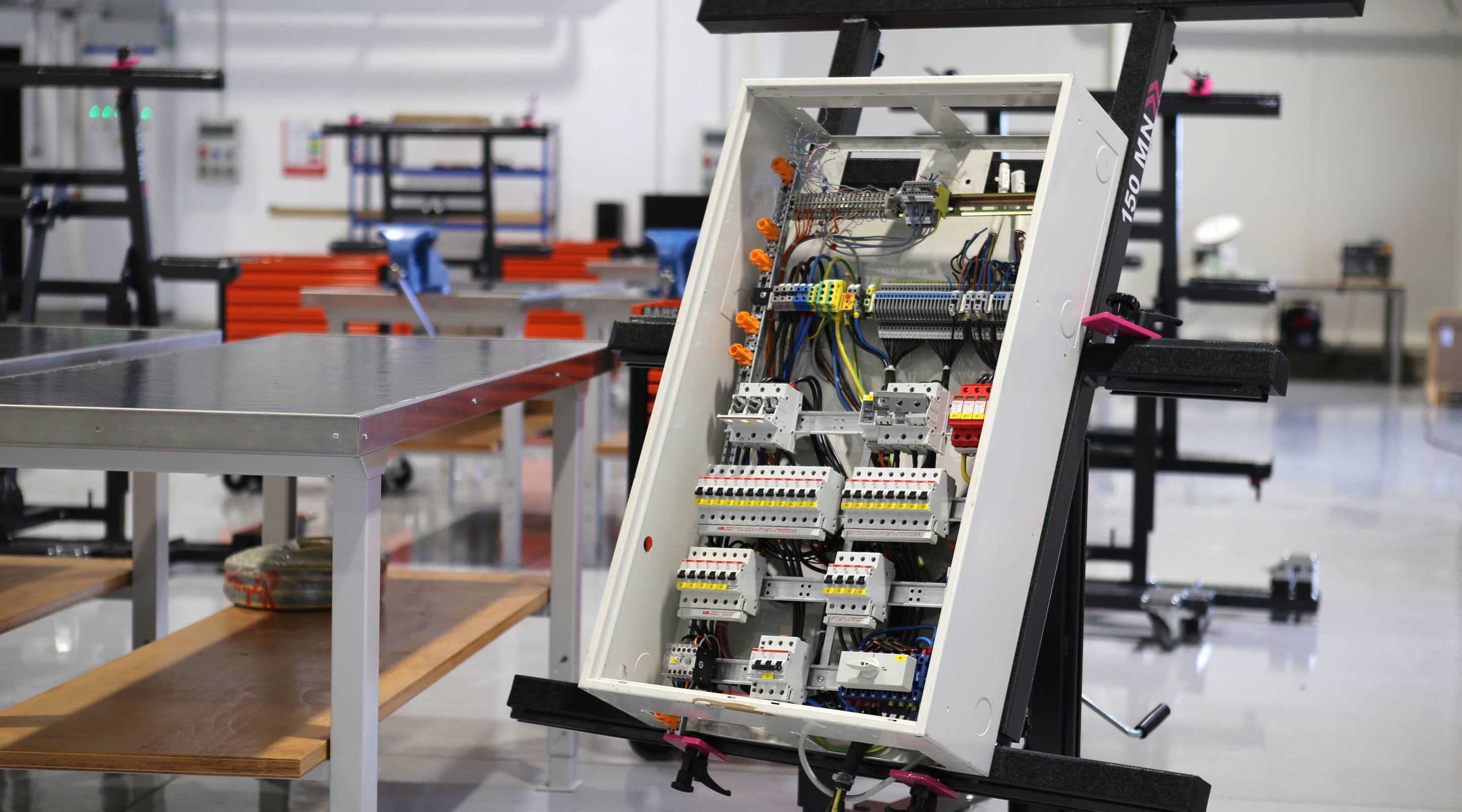

By equipping the modern plant, a new activity was launched, with an annual production capacity of 5000 electrical cabinets

A production facility that represents Industry 4.0, and enables cost reduction with suppliers, meeting deadlines, production standardization, quality control and employee education. Comcross Croatia is achieving all this with a new project, in addition to which this telecommunications and electrical company from Osijek has successfully introduced the almost linear production of electrocommunication cabinets into its business. Namely, with the introduction of a new activity, comcross opens new jobs in the production plant, and with the possibility of producing up to 15 electrical cabinets per day, they have the opportunity to produce almost 5000 electrical cabinets per year for personal needs, but also for various clients who have already shown interest in this product. With the production of electrical cabinets, comcross has enriched the range of its services, which relate to technical protection, a laboratory for testing, measuring and analyzing electrical installations, installation of solar power plants and the construction and maintenance of telecommunications networks.

Automatisation and time saving

The project came about by connecting our business and needs, since the core of our business is telecommunications, i.e. the construction, design and maintenance of telecommunication systems. In cooperation with our partners from Rittal, who work on the design of the factories, we have designed a production facility for electrical cabinets that we will also use at mobile locations. Everything is quite automated, because one engineer forwards the drawings to all the machines, which each know their part of the job, just like the employees who will be trained to use the new technology through this project – points out Slobodan Ribić, director of comcross croatia, which has already launched a training center at its headquarters in the Nemetin Eco-Industrial Zone, next to the production plant.

We start production by designing according to the client's wishes, followed by the creation of 3D models, and CNC mechanical processing of the housing and base plate, in order to create space for cable glands, pushbuttons and sensors. The cutting of all necessary elements is automated and precise, and the wiring is carried out with the help of 3D software - reveals Ivan Jakšić, production manager at comcross croatia, emphasizing that the implementation of these processes greatly saves time, so for example, wiring alone takes 75 percent less time compared to manual production.

Use of EU funds and training of workers

The entire equipment in the production plant is in accordance with the principles of Industry 4.0, both in the context of tools and machines, as well as in the part of computer equipment and software. Here we can single out EPLAN software solutions for planning and design, as well as computer equipment for various production planning processes, electrical cabinet design, as well as process monitoring and analysis. It should be noted that all equipment is co-financed by the European Union, i.e. through the comcross project – production plant, with which we were able to realize all our ideas and plans more easily – points out Marko Kolesarić, referent for EU funds at comcross croatia.

As far as professional staff is concerned, comcross fosters excellent cooperation with the School of Electrical Engineering and Traffic Engineering Osijek, with which it implements a couple of projects for training and retraining, but also for direct training of telecommunications technicians and PV system installers. That is why the entire new building was formed as a training center, which, in addition to the canteen and locker room, has classrooms and examples of telecommunication networks and an electrical cabinet factory, where participants immediately master the practical part of the training. Comcross used to conduct all types of training in Germany, but now the training center and production plant allow it to educate quality workers at the local level.

The entire equipment in the production plant is in accordance with the principles of Industry 4.0, both in the context of tools and machines, as well as in the part of computer equipment and software. Here we can single out EPLAN software solutions for planning and design, as well as computer equipment for various production planning processes, electrical cabinet design, as well as process monitoring and analysis. It should be noted that all equipment is co-financed by the European Union, i.e. through the comcross project – production plant, with which we were able to realize all our ideas and plans more easily – points out Marko Kolesarić, referent for EU funds at comcross croatia.

As far as professional staff is concerned, comcross fosters excellent cooperation with the School of Electrical Engineering and Traffic Engineering Osijek, with which it implements a couple of projects for training and retraining, but also for direct training of telecommunications technicians and PV system installers. That is why the entire new building was formed as a training center, which, in addition to the canteen and locker room, has classrooms and examples of telecommunication networks and an electrical cabinet factory, where participants immediately master the practical part of the training. Comcross used to conduct all types of training in Germany, but now the training center and production plant allow it to educate quality workers at the local level.

The project was co-financed by the European Union from the Recovery Assistance for Cohesion and European Territories Instrument "REACT-EU". The content of this article is the sole responsibility of comcross croatia d.o.o. for the design, implementation and maintenance of technical systems.